The Solutions You Need!

Why FDM Enterprises Titanium Tools are The Premium Choice for MRI Repair

FDM Enterprises Titanium Tools are essential for MRI repair because they are completely non-magnetic, eliminating interference with powerful MRI magnetic fields and ensuring safe, accurate maintenance. Their lightweight design reduces technician fatigue while improving control during precise repair tasks. Despite their low weight, our titanium tools offer exceptional strength, allowing them to withstand demanding service conditions without bending or breaking. Titanium’s natural corrosion resistance prevents rust and contamination in medical environments, extending tool life and supporting cleanliness standards. Built for durability and reliability, FDM Enterprises Titanium Tools provide long-lasting, professional performance technicians can depend on for safe and precise MRI service.

Why Choose FDM?

MRI-Safe Titanium Screwdriver – Key Features

- MRI-Safe & Non-Magnetic – Safe for use in MRI and medical imaging environments

- Grade 5 Titanium (6AL-4V) – Aerospace- and medical-grade alloy with exceptional strength-to-weight ratio

- Precision Machined Tips – Tips are machined, not polished smooth, providing sharper edges and improved fastener engagement

- Increased Tip Beveling – Added bevel depth increases material at stress points for greater tip strength and reduced wear

- Reduced Cam-Out – Machined geometry helps prevent slipping and rounding of fasteners

- Corrosion Resistant – Titanium resists rust and corrosion in demanding service environments

- Rubberized Ergonomic Handle – Non-slip grip designed for comfort, control, and extended use

- Lightweight & Balanced – Strong without unnecessary weight, reducing hand fatigue

- Designed for MRI Service Professionals – Built specifically for medical imaging equipment maintenance and repair

Titanium Tools

-

Titanium Metric Long Allen Key (Single) – MRI‑Safe

Regular price From $30.00 USDRegular priceUnit price / per$30.00 USDSale price From $30.00 USD -

Titanium Slip Pliers 12", 10", 8", 6" Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price From $450.00 USDRegular priceUnit price / per -

Titanium Rachet 3/8 Drive Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price $600.00 USDRegular priceUnit price / per -

Titanium Double Open End Metric Wrench Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price From $90.00 USDRegular priceUnit price / per$72.00 USDSale price From $90.00 USD -

Titanium Screwdriver Set |6 Piece| – MRI‑Safe

Regular price $284.00 USDRegular priceUnit price / per -

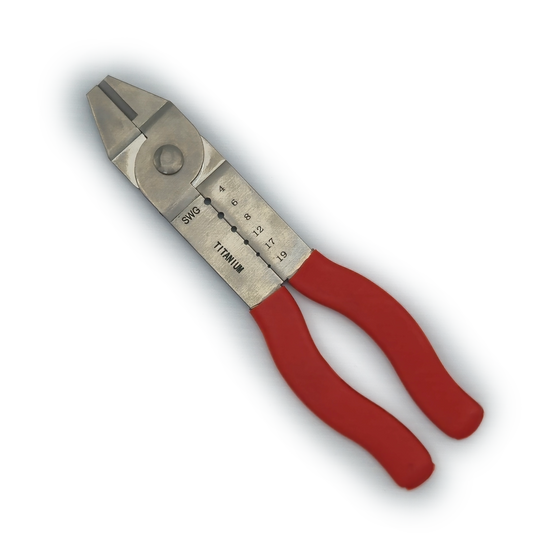

Titanium Lineman Pliers Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price From $420.00 USDRegular priceUnit price / per -

Titanium Pipe Wrench 8", 10", 12", 14"

Regular price From $352.00 USDRegular priceUnit price / per -

16 Piece Socket Set 3/8 Titanium Tool Kit – Non‑Magnetic Tools for MRI Repair

Regular price $4,200.00 USDRegular priceUnit price / per -

Titanium Long Allen Key Set – 12‑Piece Metric, MRI‑Safe | FDM Enterprises Titanium Allen Keys

Regular price $510.00 USDRegular priceUnit price / per -

MRI‑Safe T‑Handle Titanium Allen Key Set (Metric)

Regular price $290.00 USDRegular priceUnit price / per -

Titanium Metric Allen Screwdriver Handle Set |9 Piece| – MRI‑Safe

Regular price $480.00 USDRegular priceUnit price / per -

Titanium Metric Allen Screwdriver Handle (Single) – MRI‑Safe

Regular price From $40.00 USDRegular priceUnit price / per$30.00 USDSale price From $40.00 USD -

Titanium Torx Set – MRI‑Safe

Regular price $670.00 USDRegular priceUnit price / per -

MRI‑Safe Titanium Adjustable Wrench Set (10 inch, 8 Inch, 6 Inch)

Regular price $1,100.00 USDRegular priceUnit price / per -

Titanium Allen Key Set Ball End – 8‑Piece Metric, MRI‑Safe

Regular price $425.00 USDRegular priceUnit price / per -

17 + Wooden Ruler Pcs MRI‑Safe Titanium Tool Kit – Non‑Magnetic Tools for MRI Repair

Regular price $2,100.00 USDRegular priceUnit price / per -

Titanium Double Open End Metric Wrench Set 8 piece Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price $1,100.00 USDRegular priceUnit price / per -

18 Pcs MRI‑Safe Titanium Tool Kit – Non‑Magnetic Tools for MRI Repair

Regular price $2,500.00 USDRegular priceUnit price / per -

Titanium Strippers Pliers 8" Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price $350.00 USDRegular priceUnit price / per -

Titanium Universal Joint 3/8 Drive Non-Ferrous, Corrosion Resistant, Non-Magnetic

Regular price $230.00 USDRegular priceUnit price / per

Accessories

-

3 Button Optical Mouse No Scroll - Similar to HP DY651A

Regular price $30.00 USDRegular priceUnit price / per$70.00 USDSale price $30.00 USDSale